The Challenge: When Manual Systems Can’t Keep Up

One of my customers, a successful manufacturing shop owner, found himself in a familiar situation: his business had grown, but his operational systems had not. His workflow relied heavily on manual processes and spreadsheets.

The daily routine was challenging: he would open multiple Excel files, attempting to track the status of work orders. The process involved manual data entry, printing work orders for the shop floor, and relying on handwritten notes from workers to update his spreadsheets. When customers called, finding an accurate, real-time status was not possible and often required a follow-up call.

Spending hours each day for these administrative tasks, and human error was another factor, notes were sometimes lost. Critical information often resided in people's memories rather than in a centralized system.

The Solution: A Streamlined Digital Approach

We implemented a custom work order management system with real-time visibility, with the features he needed (and without bloated features like off-the-shelf software that he once tried and dropped.).

Barcode-Driven Simplicity

It's a barcode-driven process. Each work order and product step was assigned a unique barcode. Workers simply scan the code on the Order's printout, at the start and end of a process. This system eliminates manual data entry, paperwork, and the risk of forgotten updates, ensuring data is captured accurately and effortlessly.

Operational Impact

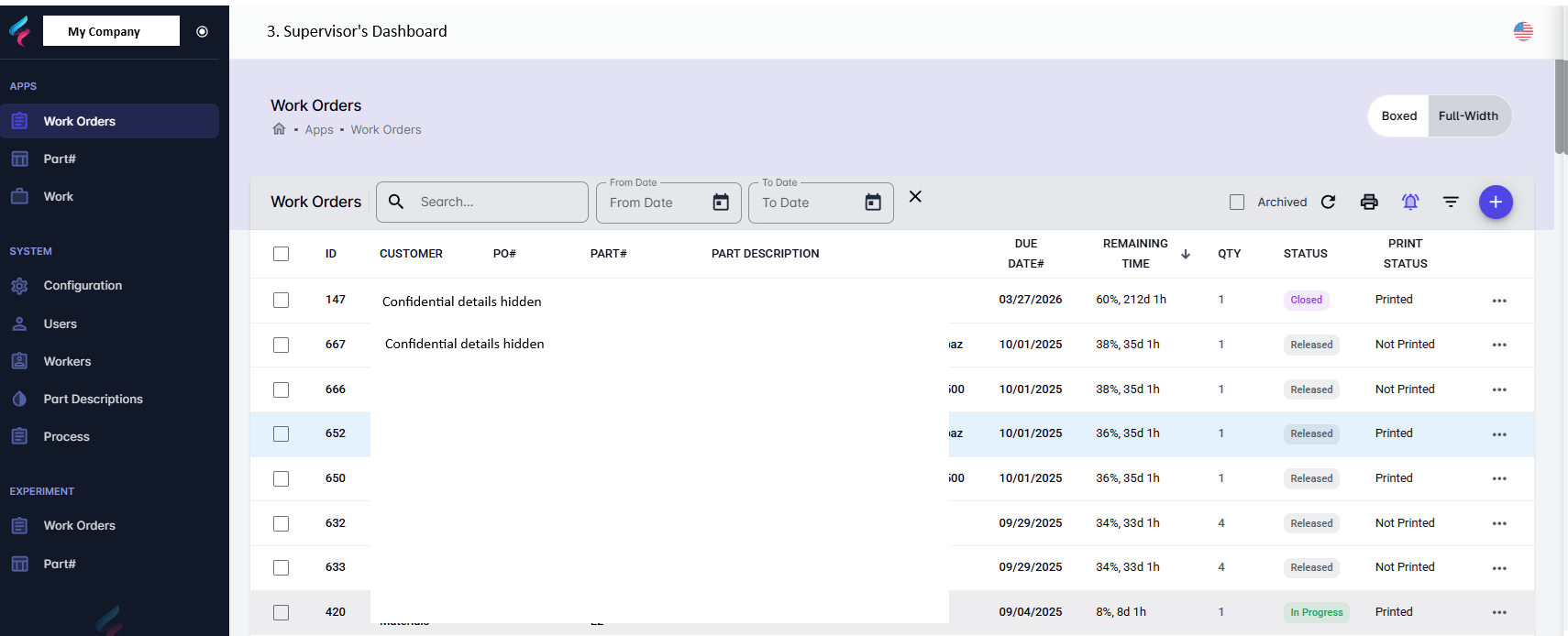

This owner now has a live dashboard that provides a clear overview of the entire shop floor:

- 📊 Real-time Status: He can see the exact location and status of every order at a glance.

- 🔍 Efficient Search: Orders can be located in seconds by customer name, part number, or order ID/order statuses.

- 📈 Progress Tracking: Visual indicators provide immediate insight into which orders are on schedule, or completed or delayed.

- 🚨 Proactive Alerts: The system sends red-flags potential issues or work delay for upcoming deadlines.

This new level of transparency also transformed customer service. When a client calls, he can easily provide a precise update on their order's progress, from the current process stage to the expected completion date.

Tangible Results

The implementation led to several key improvements:

Time Efficiency:

- ⏰ Hours daily → now is minutes to check dashboard

- 📞 Customer calls went from stressful investigations → confident updates

- 📋 Administrative overhead reduced.

Operational Excellence:

- 🎯 100% accuracy in order tracking (vs. Excel)

- 📈 Certainty of order completeion due to better visibility

- 🔄 Zero lost orders or forgotten processes

Customer Satisfaction:

- 😊 Proactive communication about delays or issues

- 📱 Instant status updates when customers call

- 🤝 Increased trust through transparency

Why This Approach Matters

If you're running a manufacturing operation and still relying on manual tracking, you're not alone. But you're also missing out on significant opportunities for growth and efficiency.

The Hidden Costs of Manual Tracking:

- ⏱️ Time waste: Hours spent searching for information instead of growing your business

- 😰 Stress: Constant worry about what you might be missing or forgetting

- 💸 Lost revenue: Delayed orders, unhappy customers, and missed opportunities

- 🔄 Inefficiency: Duplicate work, miscommunication, and human errors

- 📉 Limited growth: Administrative bottlenecks that prevent scaling

The Digital Advantage:

A modern work order management system isn't just a software tool—it's an operational upgrade. By enabling real-time data collection on the shop floor and providing a comprehensive overview of your operations.

Ready to Transform Your Operations?

My customer's story is not unique. Across industries, businesses are discovering that custom work order management systems are essential for staying competitive in today's market.

And the implementation is simpler than you might think. With modern web technologies and barcode scanning, we can have your system up and running sooner than you think.

What makes our approach different:

- 🎯 Custom-built for your specific workflow and processes

- 📱 Friendly for shop floor use, no extra, complex features that discourage the workers on the floor

- 🔧 Easy to learn with minimal training required

- 📊 Scalable to grow with your business

- 💰 Cost-effective with rapid ROI

If you’re ready to move past the limitations of spreadsheets and into a more efficient, data-driven operation, we invite you to learn more.

Contact Information is on our website: 🌐 www.myappnow.net

This case study is based on a real client implementation. Individual results may vary.